Risk mitigation is the process of systematically reducing your exposure to liabilities and the likelihood of their occurrence. Nonconforming components are a serious threat to your business because they are misrepresented as having met acceptable standards. With so many nonconforming products in the market, your business needs a reliable and trusted supply partner. Named a Top 50 electronics distributor by Global Purchasing, CTrends provides security and support through your entire product life cycle.

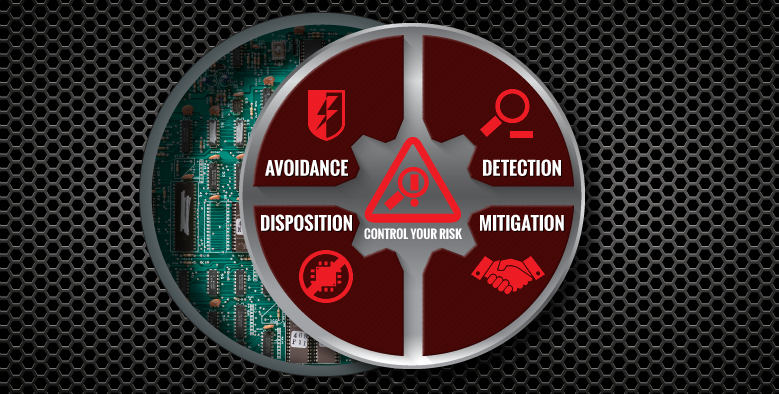

There are different risks involved in procuring electronic components and CTrends understands what it takes to mitigate those risks. Risk mitigation in supply chain management couples both risk assessment with security to provide you with continuity of authentic supply. The risk mitigation process is broken down into four stages: avoidance, detection, mitigation, and disposition. By using the stages below CTrends combats the risks that affect your supply chain.

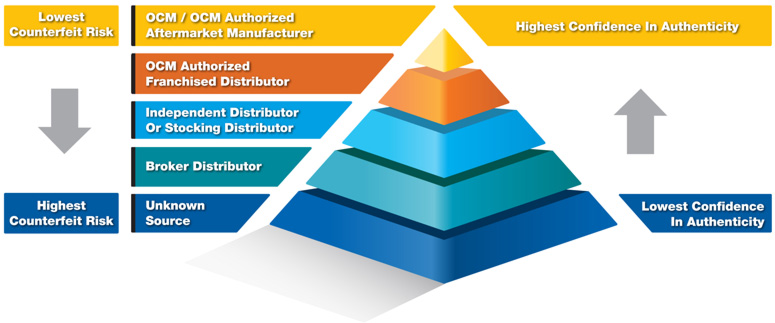

No matter how safe your quality process is, risk is always present within your project. While purchasing direct through the OCM/OEM is the safest strategy you can implement, no system is perfect no matter how many safety options are imposed. AS6496 does not account for stock rotations and courtesy returns under franchise standards. Parts sold and returned to the franchise supplier can put risk into that supplier’s inventory. At CTrends, all parts are tested and analyzed to avoid risk.

In order to minimize risk, CTrends uses processes and procedures designed to encompass AS6081 and AS6171 risk levels within the supply chain. CTrends’ implementation of a mature QMS (quality management system) along with its certifications, memberships, and alliances creates industry leadership toward reducing risk. Because of this, CTrends is a trusted supplier for the DLA and has been placed on the QTSL (Qualified Testing Suppliers List) and QSLD (Qualified Suppliers List of Distributors).

By using the CTrends’ proprietary ARC (Application, Risk, and Certification) approach, customers who partner with the company have a better chance of avoiding risk. This procedure works as follows:

A: Application of the component in the circuit.

CTrends proactively gathers the application information from its customers to provide reports that includes risk scales with parameters – in other words, an application risk assessment for your component and your project.

R: Risk: CTrends differentiates risk into 3 levels:

CTrends performs extensive risk mitigation analysis to identify and avoid potential risks. This includes supply chain analysis with supplier classification, scoring, and site audits. The database analysis of each component includes alerts, obsolescence status, and non-conforming, substandard, and suspect counterfeit notifications. CTrends also performs extensive physical evaluation during the in-house inspection & electrical testing if required.

C: Certification type, component condition, and confidence.

Along with this ARC approach, CTrends helps avoid risk with industry leading proprietary BOM (Bill of Materials) Scrubbing services. This process assists in avoiding risk by scrubbing and re-scrubbing a customer’s BOM continually throughout a product’s life cycle, an important part of avoidance with proactive component optimization.

CTrends’ proven ARC approach proactively avoids risk. CTrends also offers a robust reactive approach to risk mitigation of constrained products during the quoting process.

In order to detect risk, CTrends follows strict standards set by IDEA (Independent Distributors of Electronics Association) and required DLA programs for analysis. These include the QSLD program, which takes a product with traceability and analyzes it, along with the QTSL program, which rigorously tests products, up to full electrical test, from the open market, in accordance with AS6081 and also ANSI Z1.4 AQL (Approved Quality Level) standards; zero based acceptance plan AQL 1%.

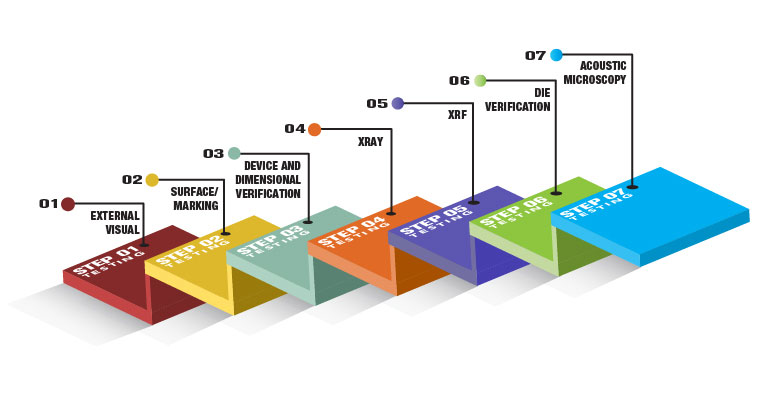

CTrends ensures the detection of nonconforming and substandard components through several testing steps.

Depending on the level of risk assessed in the application section of avoidance, our process may include:

Once tests are complete, CTrends’ certified lab technicians will generate a written test report with a certificate of analysis.

Detection is a robust stage of risk mitigation. CTrends takes pride in being an early adopter of all current and new certifications and standards.

The all new TruView™ Prime X-Ray Inspection System is a fully motorized radiography system developed to meet the stringent requirements of semiconductor failure analysis, BGA and QFN inspection, electronics assembly, and general quality inspection.

X-ray fluorescence instruments for a variety of measurement tasks, made possible through different hardware components

The PinPoint Alpha system is a flexible, adaptable and modular PCB and IC fault finding system, which allows over 50,000 different electronic test methods to obtain maximum test coverage and fault detection.

Utilizing high frequency ultrasonic transducers, the D9500 operates in both reflection and transmission modes . This non-destructive inspection capability can help identify counterfeit components in ways that extend beyond visual analysis, electrical testing, and X-ray methods commonly used today. C-SAM inspection can accurately identify internal dimensions, delamination, cracks, voids, and interface quality issues that are characteristic of counterfeit and reused components. Analysis of a component surface can also determine if a component has been remarked, identifying blacktopping, ghost markings, striations marks, and damage to the component surface. Another feature of the D9500 is Quantitative B-Scan Analysis Mode or Q-BAM which is a calibrated, non-destructive virtual cross section image of the X-Z plane of a sample.

For precise and accurate dimensional measurements

6½ digit resolution with 10 measurement functions including DC/AC voltage, AC/DC current, 2- and 4-wire resistance, diode, continuity, frequency, period.

A non-destructive inspection technique that provides real time X-ray imaging complete with reel to reel inspection capabilities. Components are inspected for homogeneity, consistency, and uniformity. X-ray analysis is used to confirm die presence, compare die size and shape, lead frame construction, and wire bond gauge and routing. Anomalies detected with X-ray analysis include broken, missing, or sweeping wire bonds, internal structural damage, inconsistencies of lead frame structure, die size and shape.

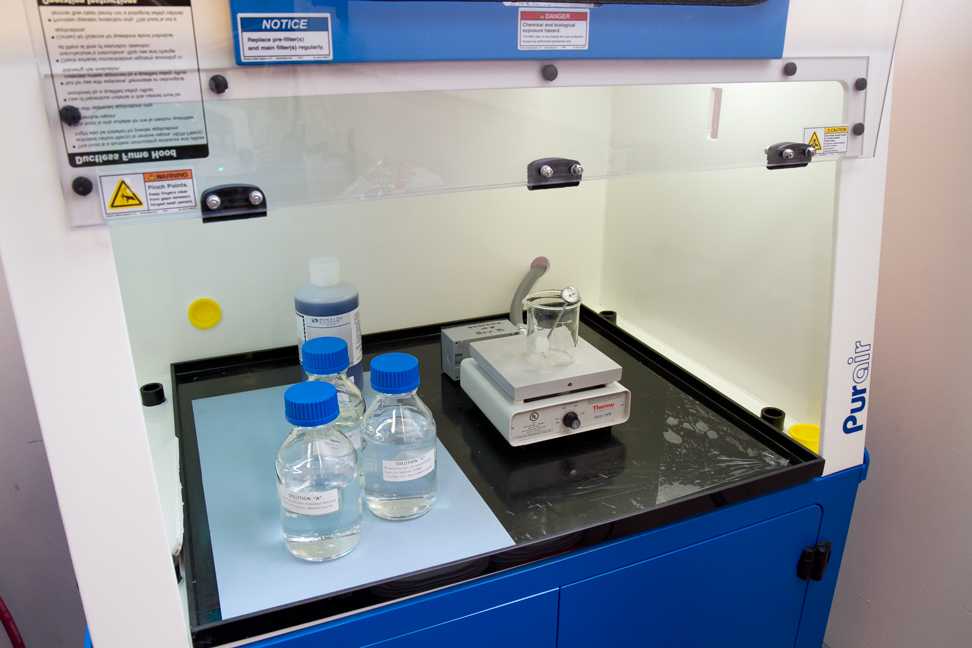

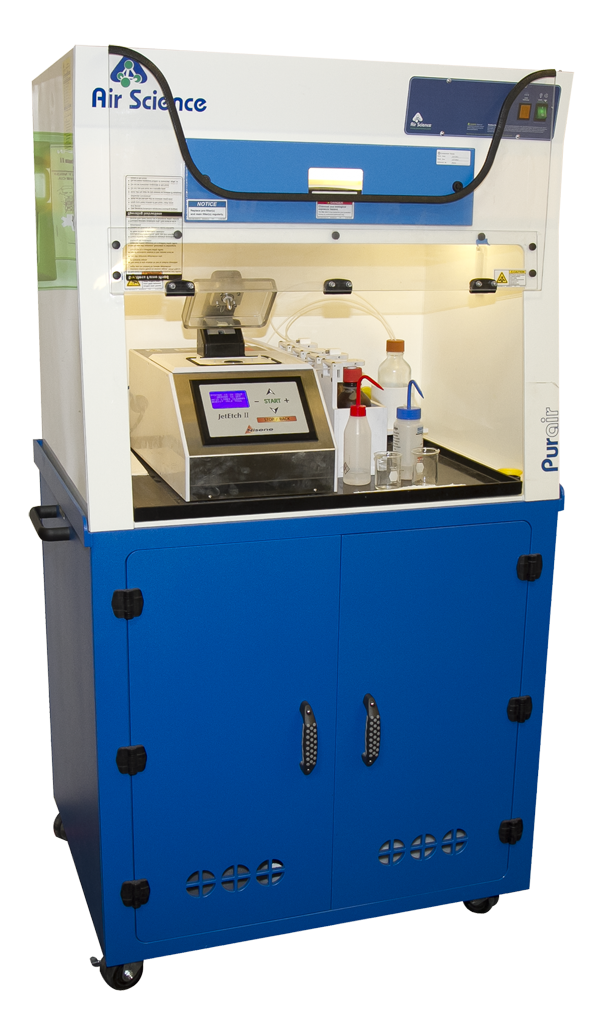

Used to perform Heated Chemical Tests.

Die verification is performed using an automated Chemical Decapsulation System. The JetEtch Decapsulation system takes an integrated circuit encapsulated in mold compound and removes it using a user-specified chemical solution. Die verification results are compared to and confirmed using CTrends, Inc. robust digital inspection library.

XRF analysis is a non-destructive test used for Lead Finish Evaluation to verify conformance to the manufacturer’s specifications, including RoHS compliance.

6.3:1 Zoom range with 6.3x-40x magnification and 10x eye pieces.

8:1 Zoom range with 15x – 120x magnification.

CTrends works to mitigate risk for your product throughout its full life cycle. By analyzing market conditions such as life cycle stage and confirmed stock in the franchise and open markets, it can provide an understanding of potential risks you and your company face. CTrends qualifies the priority for your requirements based on price, delivery, and quality.

CTrends’ BOM scrubbing report not only identifies risk, but also provides suitable crosses to allow customers additional options. Because risk mitigation is more than just eliminating counterfeit or non-conforming components, the BOM scrub service also looks for potential manufacturing constraints.

CTrends strives to remain proactive throughout your product’s manufacturing life cycle. This means not only looking for risks in the current time frame, but also in the future. For example, imagine knowing months in advance that a manufacturer of one of your critical components is deciding to discontinue that part as a result of advancing technology. This proactive review will allow you to have ample time in which to decide whether or not to upgrade your existing technology or use an alternative cross that CTrends identifies as trustworthy. This also allows you to remain competitive when new technology hits the market.

Complete risk mitigation programs will include a mature QMS as noted by third party auditors and the OASIS (Online Aerospace Supplier Information System) database. CTrends is proud to demonstrate its top industry certifications such ISO 9001:2015 AS9120B, FAA AC 00-56B, and ANSI/ESD S20.20 2014. These certifications are designed to back up the “Trusted Supplier” qualification awarded by the DLA. CTrends is a reliable source for electronic components and all of your authentic supply chain needs.

CTrends has successfully developed mechanisms to protect customers against non-conforming, substandard, and suspect counterfeit parts and at the same time established strict standards for a mature QMS. Once a product has been identified as nonconforming, substandard, or suspect counterfeit, it is immediately quarantined, segregated, confiscated, and secured. These parts are not returned to the supplier to avoid reintroduction of such parts into the supply chain. As a member of ERAI, IDEA, and GIDEP, CTrends reports all occurrences for industry notification. CTrends follows all industry protocols and has pioneered a process for reporting that includes the national IPR (Intellectual Property Rights) Coordination Center, DHS (Department of Homeland Security) and ICE (Immigration and Customs Enforcement).

Every business needs a trusted partner that understands the risks involved and how to mitigate problems before and when they occur. Whether it’s aerospace, automotive, communication or defense, CTrends understands the needs of each industry. CTrends is the only company in the U.S. that covers the four main aspects of the electronics supply chain process: component data and optimization, component distribution and procurement, risk mitigation, and excess inventory management.

CTrends will support your needs to mitigate risk throughout your product life cycle. The risk mitigation process included avoidance, detection, mitigation and disposition. CTrends optimizes each of these processes and procedures to create a safe, secure, and efficient supply chain, thereby saving you time and money. When risk mitigation is optimized every person on your team wins, whether it is the design engineers, the procurement team or the quality assurance managers. Partner with CTrends, the company that continues to champion the way for the industry.